& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

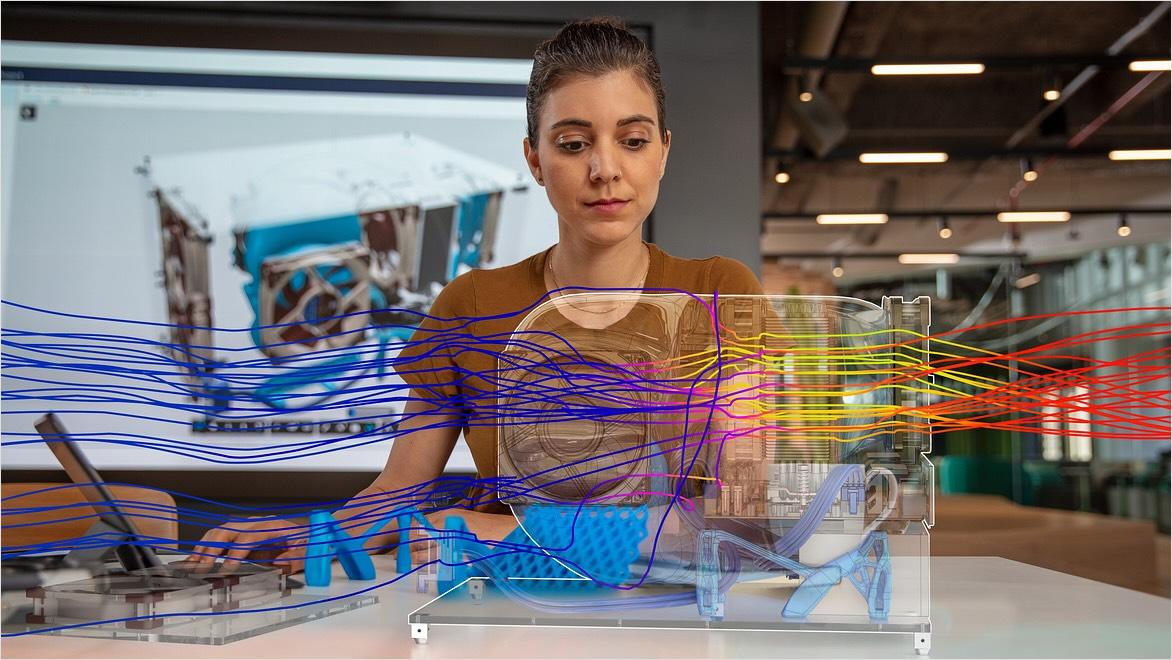

A digital thread is a software framework for data transfer and communication that unifies all product information across an entire product lifecycle. It creates a single source of truth for product data, updated in real time and unified in its presentation to all departments, including product design, engineering, and manufacturing. Throughout all product lifecycle stages, the digital thread imparts valuable insight into making products more sustainably. During the design phase, data from the digital thread can inform material choices for the least waste and the lowest carbon footprint. During the manufacturing and logistics phases, digital thread data can uncover methods with the best energy efficiency.

The use cases for a digital thread in manufacturing run through the design, product development, production, logistics, and customer service stages and have implications for regulatory compliance and sustainability as well.

During product design and development, the digital thread provides unified data access to all collaborating parties, updated in real time within a single source of truth. This fosters more effective teamwork, working toward improving product quality, reducing errors, and resolving issues before physical prototyping.

As a product goes into production, the digital thread uses design, production, and supply chain data to optimize scheduling and capacity planning. During manufacturing, the digital thread offers insight into operations with real-time monitoring of machines and equipment. Data streamed from IIoT sensors and analyzed by AI-assisted software can provide quality-control updates, such as defect analysis, and predict when production equipment will need maintenance.

Supply chain efficiency benefits from the digital thread’s data, which can reduce lead times by optimizing inventory levels and keeping suppliers up-to-date. It also helps in coordinating deliveries and logistics processes. The product lifecycle management (PLM) functions of digital thread software impart end-to-end traceability of a product and its constituent parts. The detailed documentation, reporting, audit trails, and analytics of a digital thread help with regulatory compliance.

A digital thread can impact customer satisfaction and loyalty because its product lifecycle data is available to improve the customer experience and results from product upgrades, repairs, and maintenance. Detailed product history and maintenance records aid aftermarket servicing, and the resulting data from after-sales servicing and customer feedback informs the development of new and better product versions.

A digital thread connects every organizational department with product lifecycle data, encompassing product quality, customer service, regulatory compliance, and more. Its benefits are widespread, including:

The digital thread connects data between all business processes, for example between engineering and manufacturing, optimizing communication and collaboration throughout all company departments and stakeholders.

Clear insights from the digital thread’s connecting information come from all sides, including design, manufacturing, logistics, and even customers, creating fertile ground for product innovation and maximizing productivity for developing and shipping products faster.

With a digital thread in place, all product lifecycle information can be tracked, such as design and engineering data and maintenance records. That makes it possible to automate certain reporting tasks for regulatory and quality compliance.

Digital thread’s seamless data flow can improve efficiency, automate repetitive tasks, and reduce manual data entry, saving time and reducing errors.

The digital thread can collect and analyze product quality data and product usage data, creating a data feedback loop for product improvement. Captured data can also validate to customers that a product is responsibly sourced.

Crucial product maintenance and service information can pour straight from the engineering department into product service documentation, boosting customer satisfaction with faster and more successful product servicing.

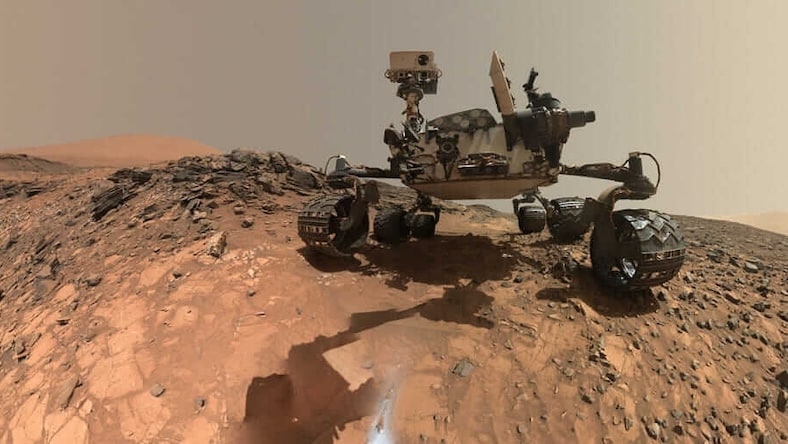

Digital threads and digital twins are complementary technologies within the digital transformation journey, yet they are distinct concepts. Specifically, a digital twin is a virtual representation of a physical counterpart, whether a single product or a complex asset or system like an office building or factory. Digital twins simulate and optimize the performance of their physical counterparts with real-time data feedback.

A digital thread, on the other hand, is a technological framework for seamlessly passing comprehensive product lifecycle information through every department of an organization. Digital threads provide data continuity that spans an entire product lifecycle, from conception to disposal, and enhance collaboration, traceability, data integrity, and compliance.

Both connect to real-time data collection and analysis to provide insights into achieving better performance. However, digital threads have a broader scope and can integrate one or more digital twins to produce more efficient design, manufacturing, and maintenance workflows.

Industry 4.0 integrates a host of digital technologies, including cloud computing, artificial intelligence, IIoT, and big data, to enable digital factories and smart manufacturing. Digital threads combine Industry 4.0 technologies and initiatives into a coherent whole for smarter, more efficient manufacturing processes.

A constant output of data runs through the digital thread, connecting the entire manufacturing ecosystem. Cloud-powered digital thread software platforms integrate massive data flows from IIoT devices and sensors with data from various software systems, including CAD (computer-aided design), PLM (product lifecycle management), ERP (enterprise resource planning), and MES (manufacturing execution systems) software. This promotes better interoperability between machines and systems, as well as better informed, more effective decision-making.

Automation is a core tenet of Industry 4.0 smart manufacturing, and the digital thread provides hardware and software systems the data they need to streamline operations, reduce errors, and improve productivity. Machine learning and AI-assisted robotics fed by the digital thread’s data perform automation like quality control checks, complex assemblies, predictive maintenance, and adaptive processes that make manufacturing more responsive and flexible.

The digital thread supports other advanced technology that is changing the methods and results of manufacturing for the better, for example, augmented reality (AR) and virtual reality (VR). These technologies can make on-the-job training faster and more effective or give real-time instructions, for example, from AR data and visualization overlays. Cobots (collaborative robots) also owe their growing popularity to integration with the digital thread. Connecting cobots to real-time data updates helps them work more effectively alongside humans.

Digital thread software solutions integrate data from existing manufacturing systems—including CAD, ERP, and MES tools—to transfer a unified data stream across all departments of manufacturing operations. This can be achieved through several methods, including APIs (application programming interfaces) that interconnect different software systems, various open data standards, and data integration platforms that translate data formats.

Digital thread solutions also integrate real-time data from IIoT sensors and devices, then use security measures like data encryption and/or permissions technology like role-based access control (RBAC).

By universally integrating data from all sources, a digital thread can facilitate the most effective, comprehensive data analytics and workflow automation. It can also provide customizable dashboards with real-time data from all manufacturing systems. Altogether, a digital thread supplies a holistic view of manufacturing data, operational efficiency, and the product lifecycle.

GREENLANE RENEWABLES

Autodesk’s cloud-based PLM solutions helped Greenlane Renewables make its biogas upgrading business more efficient and profitable by establishing a digital thread for seamless data transfer between enterprise systems, reducing unnecessary costs, and realizing economies of scale in its bill of materials.

VACCO INDUSTRIES

VACCO Industries created a digital thread through its space and defense engineering business by implementing the PLM automated processes and centralized data of Autodesk Fusion Manage. Find out how the firm improved the visibility of its operations and improved product quality and efficiency.

WOODWAY

The world’s largest specialized treadmill manufacturer wanted to improve collaboration between its different departments and its suppliers. Autodesk’s cloud PLM solutions helped in the process, and the resulting digital thread also reduced errors and improved output.

As key Industry 4.0 technologies like AI, digital twins, and the IIoT become even more powerful and capable, the digital thread will connect data insights and make predictive adaptations more effective, reducing costs and downtime. More powerful technologies will allow the digital thread and its connected systems to do even more simulation and optimization within the virtual realm, conserving physical resources.

Any supply chain uncertainty necessitates more data transparency, allowing the digital thread to pull together the least environmentally taxing supply chain and to have greater transparency into ethical and sustainable material sourcing and production practices.

It will also become easier and more affordable for small and medium-sized enterprises (SMEs) to implement digital thread software solutions, allowing their benefits to efficiency, sustainability, and data-driven decision-making to fan out to the entire manufacturing base.

Dig into the benefits of product lifecycle management (PLM) for creating a digital thread in manufacturing and what to look for in PLM digital thread software.

Some key factors differentiating PLM from product data management (PDM) have to do with PLM’s comprehensiveness and its ability to integrate with other enterprise systems like ERP, MES, and CRM systems.

Take a peek into Fusion Manage’s powerful, flexible, and scalable product lifecycle management capabilities. This cloud-based digital thread software standardizes and streamlines product design, manufacturing, and business processes.

Like components in an assembly, digital twins are essential sub-systems within the larger digital thread in manufacturing. Read more about digital twins’ benefits and applications in manufacturing.

Get the PLM solutions that are right for your business, as well as the resources to simplify a successful PLM implementation.

A digital thread is an essential element of a manufacturer’s digital transformation journey. It is a data communication framework that unifies product information across a product’s lifecycle. It creates a single source of truth for product data, updated in real time and unified in its presentation to departments of product design, engineering, and manufacturing. A digital thread creates better visibility, collaboration, and decision-making throughout the lifecycle of a product.

The difference between a digital thread and a digital twin is largely a matter of scale. Both concepts are digital re-creations of physical-world counterparts, which use collected data to simulate real-world operations and provide insights.

A digital twin represents and collects real-time data from a single product or asset, even if that asset is large and complex like an entire office building or a factory. A digital thread, on the other hand, connects the data, processes, and workflows from an entire enterprise as it pertains to the lifecycle of a product or system. That can include one or more digital twins, as well as data from all of the enterprise’s departments and systems.

The challenges of implementing a digital thread into a business include attaining buy-in from the C-suite, which is important for ensuring a commitment to successful implementation. Even with executive buy-in, there may be other internal resistance to the changes a digital thread will cause.

In addition, there are the logistical challenges of allocating and prioritizing the budget for a digital thread, as well as the technical challenges of identifying, acquiring, and installing the proper technological systems and data collection.

PLM stands for product lifecycle management, a core ingredient of the digital thread. PLM is an end-to-end approach to managing all aspects of a product’s lifecycle, from initial concept and design, to manufacturing, maintenance, and through to disposal. PLM software like Autodesk’s cloud PLM solution, Fusion Manage, handles all data related to a product’s design, production, and support.

PLM data includes CAD (computer-aided design) files, engineering documents, bills of materials (BOM), and other data. PLM may also connect data from SLM (service lifecycle management) and ALM (application lifecycle management) systems, which respectively handle product service-related data and software engineering data.

Yes, SMEs can benefit from implementing a digital thread in several significant ways. For example, a digital thread’s unified data source improves collaboration among internal colleagues and external partners, contractors, and clients. A digital thread’s seamless data flow connects all phases of a product’s lifecycle, improves efficiency, and promotes quality control by exposing potential problems early in the process.

A digital thread provides a traceable history of a product’s development, making regulatory compliance easier. Using this connected and instantly updated data on the product lifecycle also leads to better decision-making.

The digital thread enhances PLM (product lifecycle management) because it connects data from every stage of the product lifecycle and unifies it in a centralized cloud platform for all stakeholders to access and/or edit. This makes collaboration faster, easier, and more effective.

With a digital thread, product developers can monitor product performance in real time and track any changes with traceable data. It helps them make better-informed decisions, as well as save time and costs due to streamlined processes.