& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

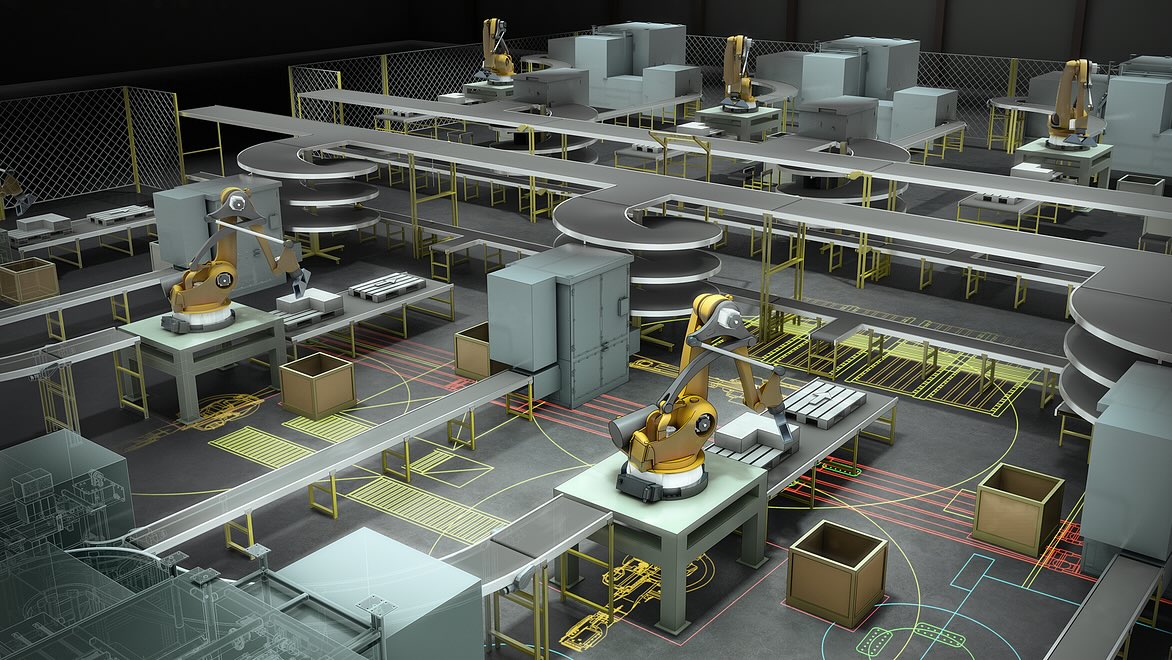

3D software helps designers visualize and plan efficient manufacturing plant layouts.

A manufacturing plant layout is the organization of physical elements within a factory, including machines, workstations, storage areas, walkways, and even human workers and mobile robots moving through the facility. Using advanced 3D software can help designers develop the best manufacturing plant layout, which will boost the overall efficiency and productivity of the factory and its staff, as well as mitigate waste and costs.

Lean plant layouts are intentionally designed for efficient flow and minimal waste. Image courtesy of Vimek.

A lean plant layout applies the principles of lean manufacturing to eliminate as much waste as possible from the manufacturing operation: excess time, money, materials, and motion. Depending on the factory’s production, a lean plant layout may zone jobs like cutting, organizing, and packing into separate spaces; it may put processes in sequential order for each product; or use a combination of the two. Regardless of a factory’s specific needs, a lean plant layout achieves the smoothest and most efficient flow of material and data across the factory floor. Done well, it results in lower costs, faster lead times, improved worker safety and morale, and higher productivity and product quality.

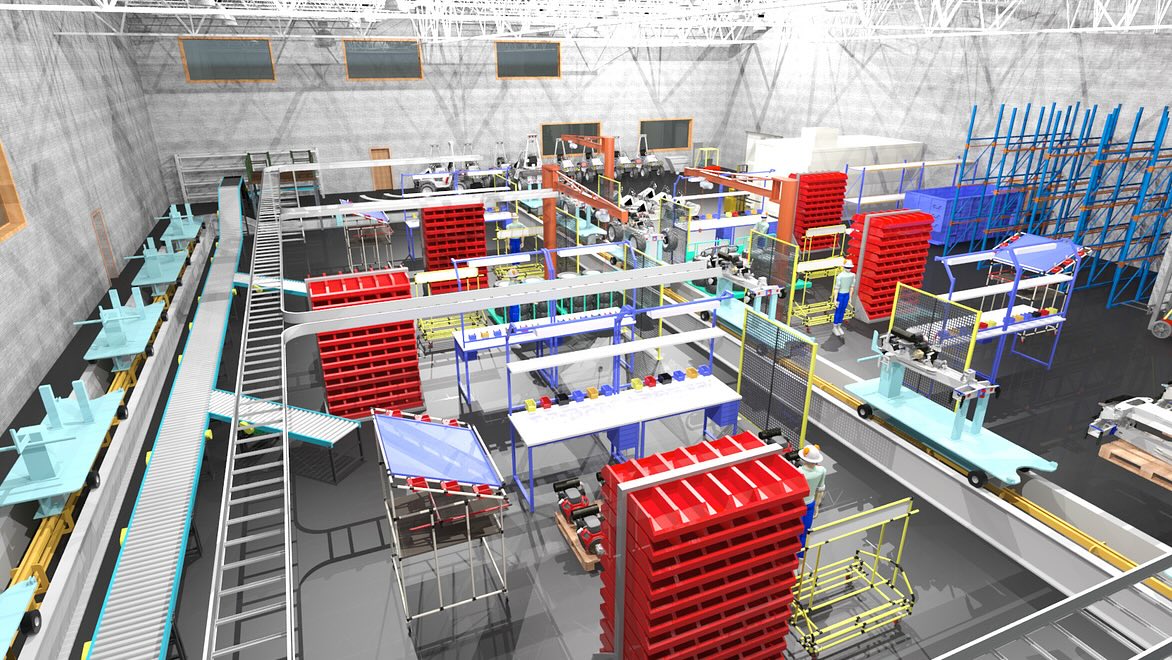

The products and processes involved influence the type of layout chosen; for example, large assemblies like construction modules may require a fixed-position or combination layout.

A lean plant layout can follow five different types of manufacturing plant layouts: process, product, cellular, fixed-position, and combination.

A process layout is flexible and positions similar processes or machines in clusters, while product layouts place machines and workstations in the appropriate sequential order for a product line. Product layouts are less flexible but are fast and highly efficient for mass production, while process layouts can be better for batch production.

A cellular layout blends the process and product layout approaches with machine cells that make groups of parts or assemblies. Often in a cellular layout, each cell’s team makes a product from start to finish, with each person involved in multiple tasks.

In a fixed-position layout, the product remains in a fixed position while machines and employees work around it. This layout usually suits very large products or assemblies that are impractical to move around in manufacturing facilities. Finally, a combination layout is any production layout that combines elements of the other layout types.

Designing a manufacturing plant layout follows several steps before and after the bulk of the design work in 3D layout software:

Begin by understanding your company’s or your clients’ needs for the manufacturing facilities layout. Determine key factors like the desired business outcomes, the desired workflows and processes that need to be optimized or automated, and the equipment and floor space that is available or needed.

Now it’s time to start planning the production processes and material flows. This step involves a rough initial layout such as a flowchart or a 2D orientation of how equipment will be positioned and how material will be handled to move through the production lines efficiently.

The type of manufacturing plant layout you choose can make a big difference in how flexible or efficient the final processes are. Settling on one or more layout types as detailed above—process, product, cellular, fixed-position, or combination—will set the direction of your overall manufacturing facilities design.

As the actual design begins, it helps to know the precise sizes, movements, constraints, and other characteristics of the robotics, machines, and other equipment to be included in the 3D CAD model. The equipment should complement your layout type and process workflows. Designers can experiment with the optimal placement and orientation of equipment, storage space, and walkways to encourage the production volume and product variety of the factory.

Manufacturing plant layout software can test and validate the layout design using simulation to show the whole picture of how materials, products, workers, and machines will interact. Software simulations can detect problems and suggest fixes using data and visualizations. After validating that the layout design meets or exceeds expectations for speed, productivity, adaptability, and safety, they can confirm the final design.

After implementation, it is essential to continuously monitor the performance of the layout to ensure it meets the desired objectives. Collecting feedback from employees and managers is crucial for identifying areas that may need adjustments. By making necessary improvements based on this feedback, efficiency can be enhanced, and any issues can be promptly addressed.

Get Inventor + AutoCAD + Autodesk Fusion + more—Professional-grade tools for product development and manufacturing planning.

Using 3D software to create the best possible production layout plan at your factory results in a variety of operations benefits that can increase profits, including:

Square footage is expensive. Get the most value by experimenting with equipment and workstation locations, rotations, and orientations in software before committing to physical changes.

Tinkering with different layout strategies in software helps you discover which one will move quicker, for example—a product layout or process layout that splits the factory into different zones can save time.

Seeing everything laid out in a dynamic 3D model makes it easier to spot potential shortcuts or efficiencies from making small tweaks to the layout.

A manufacturing plant layout optimized in software can trim time off multiple steps in the production of a product for a more efficient operation and a reduced product cycle time.

Companies can streamline production with a redesigned manufacturing plant layout to make the most of the existing space and handle materials in the most efficient way.

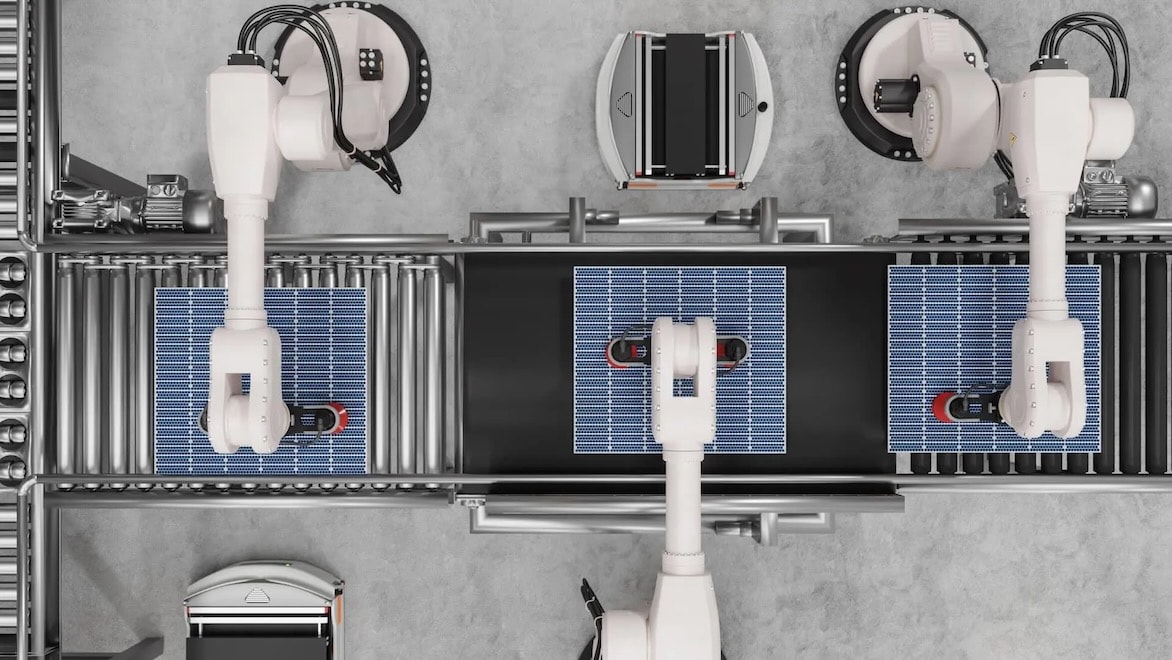

Automated systems and conveyors, including autonomous robotics, contribute to a fast, continuous flow of products and materials throughout factories and warehouses—as well as making the human workforce more efficient and productive. Automated guided vehicles (AGVs) are robots that travel along preset paths defined by sensors or magnets, and autonomous mobile robots (AMRs) have sophisticated computer vision from cameras and/or LIDAR to navigate facilities without predetermined routes.

Automation can help reduce repetitive or unproductive tasks for workers; the plant layout should also optimize the space to make workers’ everyday tasks efficient, ergonomic, and accessible. Leaving sufficient space between factory elements can help workers and autonomous systems transport materials and avoid bottlenecks.

The smooth, continuous flow of information and data also affects efficient material handling and space utilization. This includes both the clear communication between supervisors and employees, as well as the communication between the machines and devices within the factory. For example, a digital factory connected with Industrial Internet of Things (IIoT) sensors and devices on its production lines collects an enormous amount of data from everyday operations. Fed into cloud-connected and AI-assisted manufacturing operations software, that data can generate predictive maintenance alerts and provide insights to improve the flow of operations, efficiency, safety, and much more.

While designing a manufacturing plant layout is a large endeavor presenting many challenges, solutions depend on the practical use of modern technology.

Designing and implementing a manufacturing plant layout requires a sizable upfront investment of time and money. It may even require downtime for certain processes or workstations. There’s also the issue of maximizing limited floor space while maintaining flexibility and scalability to accommodate future changes and new business opportunities. Finally, a business may experience employee pushback if the factory staff isn’t on board with the changes from implementing a new layout.

Using manufacturing plant layout software can mitigate these challenges. Digitizing representations of the entire factory—including equipment, buildings, and even people—and making a single, up-to-date model for all stakeholders to see and contribute to can make the plant layout process as efficient as possible. Costs of downtime and implementation can be minimized and deferred while problems and conflicts are worked out within the model. Different options for using the available space can be explored digitally using simulations and 3D visualizations, which in turn can show employees how these changes may result in better day-to-day conditions.

VIESSMANN

German company Viessmann explored advanced digital factory planning for its heat pump facility, incorporating laser scanning, 3D visualization, and augmented reality for better precision and efficiency. It used Autodesk BIM 360 (now Autodesk Construction Cloud) for manufacturing plant layout design and checked the 3D model with Autodesk Navisworks advanced simulation and clash detection.

Image courtesy of Viesmann

TESLA/GOLDBECK

To make the Tesla Gigafactory 4 the fastest-built factory in the world, construction firm GOLDBECK treated the building like a product, using standardized components, prefabrication, and scalable series production. It also automated as much of the digital manufacturing plant layout using cloud-based Autodesk BIM 360 (now Autodesk Construction Cloud), which cut the build time by a third.

Image courtesy of GOLDBECK

THREDUP

To design a new, automated layout for its distribution centers, ThredUp’s floor layout process made use of Autodesk FlexSim, AutoCAD, and Navisworks. The popular online resale platform experimented with different layouts, simulated future operations, and validated its production capacity.

Read about the importance of factory simulation software for creating optimal manufacturing plant layouts. Simulations provide insight into building efficiency, productivity, consistent quality, and flexibility.

Find out more about Autodesk’s factory design solutions, with abilities for creating digital twin simulations and capturing data-based insights, benefits for keeping plans on schedule and on budget, and much more.

To execute a plant layout design for the most efficiency and flexibility, you want the best CAD software for your goals of optimizing throughput, reducing errors, improving time-to-market, and more. This downloadable PDF outlines the software features and abilities to prioritize.

With discrete event simulation (DES), manufacturers virtually test and validate “what if” scenarios so they can make informed decisions that promote innovation, improve efficiency, and reduce costs. This e-book tells you how to utilize DES without disrupting real-world production.

Discover a new workflow for manufacturing plant layout using Autodesk Factory Design Utilities and FlexSim in this Autodesk University session. The presentation emphasizes the importance of connected data and the ability to validate plant layout designs in software platforms.

Check out how collaborative manufacturing plant layout software can make interfacing with stakeholders a breeze during plant layout design. This Autodesk University session shows how producing a plant layout in Autodesk Factory Design Utilities and collaborating in the Autodesk Construction Cloud can make the process as productive as possible.

A lean plant layout is a manufacturing plant layout that applies the principles of lean manufacturing. In essence, lean manufacturing seeks to minimize or eliminate waste in all forms, including wasted time, wasted money, wasted worker productivity, and so on. A lean plant layout strives for the smoothest circulation of material and information throughout the factory floor while optimizing every inch of that floorspace for efficiency and/or flexibility. A well-executed lean plant layout results in lower costs, faster lead times, higher product quality, and higher employee productivity from improved worker safety and morale.

A process-based manufacturing plant layout is a more traditional, siloed approach—for example, a facility might be divided into separate, process-based departments for machining, assembly, surfacing, and so on. This approach can potentially handle a wide variety of products, but can also require long lead times for moving materials between departments.

With a value stream–focused manufacturing plant layout, processes are ordered horizontally for an efficient and straightforward material flow from one process to the next—potentially extending from raw materials to the final product. This reduces lead times and waste.

The characteristics of a good plant layout include the efficient flow of materials, products, and personnel, and the best possible utilization of space. To achieve that, the manufacturing plant layout should aim to minimize material handling and have all areas to highly visible, accessible, and well-coordinated between departments.

Other important characteristics include making the plant layout flexible enough to accommodate changes to production, future-proofing it for changing technologies and market conditions, employee safety and ergonomics, minimal waste, and cost-effectiveness.

The five types of production layouts are product, process, cellular, fixed position, and combination layouts.

Planning and designing a manufacturing plant layout requires many steps, starting with understanding the requirements for the layout based on products, product volume, and workflows. With that determined, an initial workflow analysis can determine the type of layout needed.

Next, the design can begin with determining specific equipment to use and plugging their dimensions into the layout. You should experiment with the equipment layout to establish the most efficient material handling, production workflows, and worker safety. Manufacturing plant layout software can simulate operations within the factory model, helping find and fix problems and tweak the design for future flexibility and scalability.

The primary factors to consider when designing a plant layout are efficiency and productivity stemming from best practices in space utilization and material handling. Key ways to achieve that include reducing repetitive or unproductive tasks for workers, avoiding bottlenecks and downtime in production lines, establishing clear communication between supervisors and employees, and setting up a fast, continuous flow of products and materials.

Factory Design Utilities, available only within the Autodesk Product Design & Manufacturing Collection, is tailor-made software to help design a manufacturing plant layout. It allows users to visualize an entire factory layout in a comprehensive 3D model, including machinery, equipment, workstations and more.

The 3D discrete event simulation software FlexSim is another purpose-built option for modeling a manufacturing plant layout and analyzing and optimizing its operation through powerful simulations, 3D visualizations, and animations. Its data-based insights into factory operations, labor, materials, and more aid decision-making for plant layout designs. FlexSim enables software simulations of many plant processes, like material movement, machine operations, and the interaction between different factory elements, so users can improve efficiency within the model.